The Ultimate Guide To Mhs - Material Handling Supply Inc.

The Ultimate Guide To Mhs - Material Handling Supply Inc.

Blog Article

The smart Trick of Mhs - Material Handling Supply Inc. That Nobody is Talking About

Table of Contents7 Simple Techniques For Mhs - Material Handling Supply Inc.The 10-Minute Rule for Mhs - Material Handling Supply Inc.All About Mhs - Material Handling Supply Inc.Get This Report on Mhs - Material Handling Supply Inc.The Greatest Guide To Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. for Beginners

This line is called the line of action. forklift rental watkinsville, ga. If all-time low of this line goes outside of the stability triangle since a lots is also hefty or also high, or since the forklift is out a degree surface it will certainly topple. An upright line expanding from the facility of gravity of the vehicle-load combination should stay inside the security triangle to stop the forklift from tippingThis security triangular is made by attaching both front wheels and the pivot point of the rear axle. The various other principle to understand is the forklifts center of mass. Notification that the front and back sides of the stability triangle are high-lighted. When unloaded, the forklifts center of mass is ideal regarding right here.

Larger lots shift the center of gravity forward also further. Raising the load additionally changes the center of mass forward. In order to prevent the lift from tipping, the consolidated facility of gravity of the lots and the lift should stay inside the stability triangle (at ground degree) in all times.

Little Known Facts About Mhs - Material Handling Supply Inc..

If you have a well balanced tons, the lots is not likely to affect the side-to-side center of gravity. https://mhsinc30677.start.page. If you drive on a sloped surface, your center of gravity might pass outside of the stability triangular and the lift might tip. Every forklift has a recognition plate that details vital details about the truck

To make sure that the center of mass of your forklift stays inside the security triangle, do not try to lift anything larger than the recognition plate permits. Regardless of just how active you are, you should evaluate your forklift prior to utilizing it. If you do find something that might impact the safety of the automobile you need to report it quickly.

Remember, the driver is liable for the risk-free procedure of the forklift. If the forklift is made use of around the clock, evaluate it either prior to each change or after each shift.

Some Known Facts About Mhs - Material Handling Supply Inc..

It is finished in two components: the walk-around examination, and, the seated inspection. It's a great idea to have a list to make certain you don't miss out on any type of steps.

If the forklift is an exterior forklift with pneumatically-driven tires, inspect the air stress and look for excessive wear on the tires. A tire with low air stress might create the lift to tip when a tons is raised.

Mhs - Material Handling Supply Inc. Things To Know Before You Buy

Inspect the engine for any indicators of wear, loosened connections, or leaks. Look for splits or deformities in the forks, back-rest, pole, and overhanging guard. Check the recognition plate to make sure it is intact and understandable.

Beginning the engine. Always begin the engine while seated in the driver's positionnever while standing together with the forklift. Inspect all determines and advising lights, and the battery or fuel degree. Get acquainted with the controls. Raise and reduce the forks, and tilt the pole. Make certain that every little thing works smoothly and is clearly classified.

Mhs - Material Handling Supply Inc. - An Overview

You'll require to appear the horn at intersections, and wherever vision is obstructed. Check the brakes by depressing the brake pedal. There need to be some resistance. Set and check the hand brake. Check the steering. A great deal of play or difficult steering will minimize your control. Relocate the forklift ahead a couple of feet.

Look for triggers or flames coming out of the exhaust system. If you discover anything wrong with the forklift during the walk-around or seated evaluation, do not operate it till it has actually been fixed.

All About Mhs - Material Handling Supply Inc.

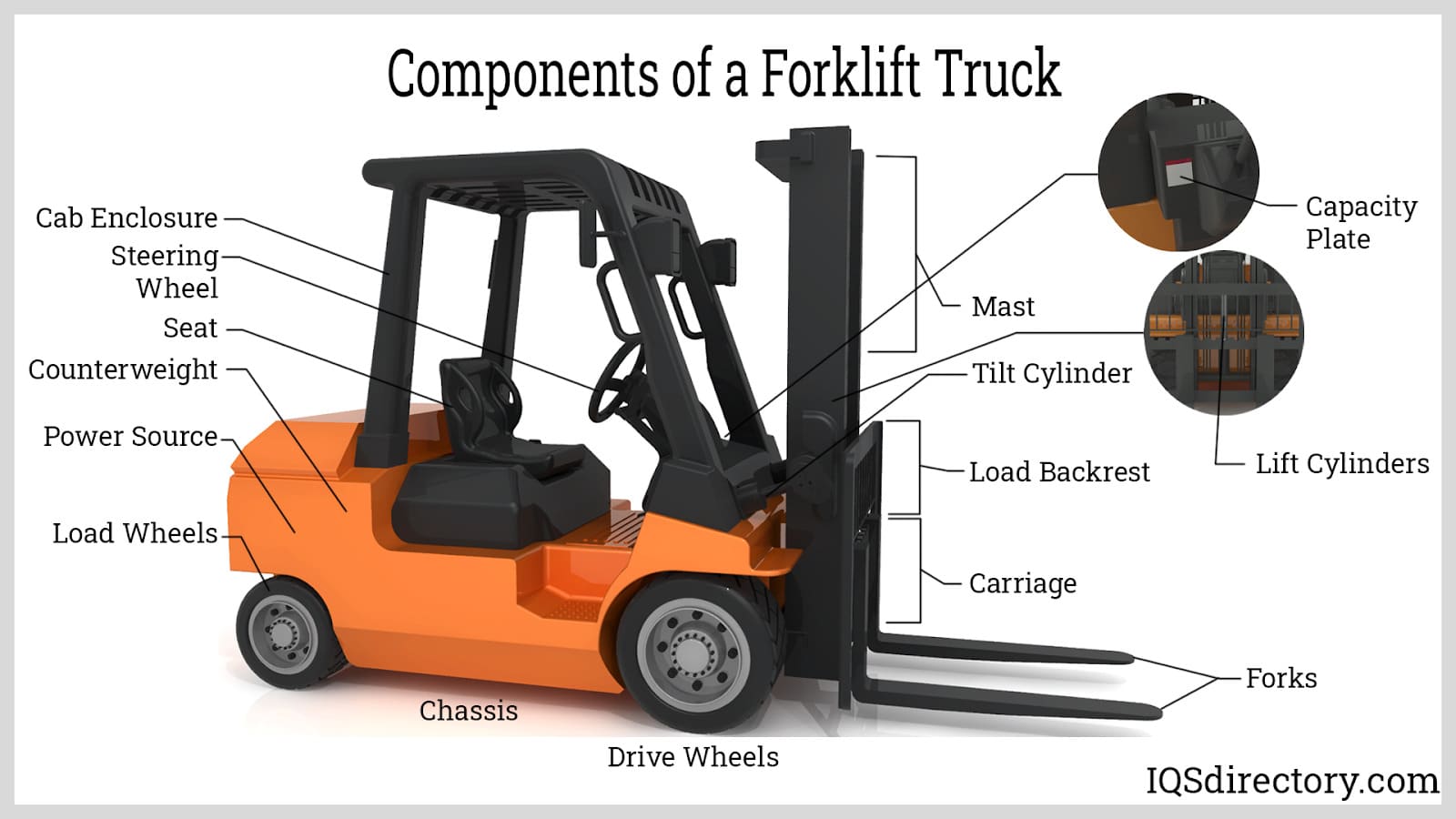

Forklifts have several relocating components and pieces that allow the forklift to run effectively. Understanding the terminology of the parts and anatomy of a forklift is essential for reliable communication with others while on duty - https://visual.ly/users/tannergraves30677/portfolio. Here are several of the essential functions and components that comprise the anatomy of a forklift truck

For most forklifts, the pole is developed more towards the front of a forklift and straight in the forklift driver's line of vision. Forklift poles come with numerous sections that elevate or reduced the forklift carriage along with the forks.

Report this page